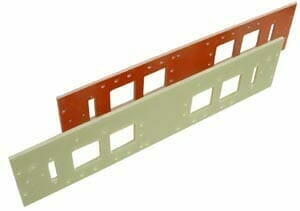

What is Platen Thermal Insulation?

Platen Thermal Insulation, most commonly referred to as Mold Platen Insulation (MPI), is an insulating material characterized by high compressive strength and heat resistance. It is commonly manufactured by a fabrication company. It prevents heat transfer between the mold or die and the platen by acting as a barrier. MPI is commonly found in injection molding, compression molding, thermoforming, and rubber molding machinery.

This type of insulation is ideal for reducing heat loss and allowing for faster mold setup, which leads to cost savings and increases the service life of machinery in a plastic fabrication company.

- Thermal Conductivity

- Temperature

- Compression Strength

- Thickness Tolerance

The thermal conductivity of the material may be the most significant factor. Heat transfer between the platen and the mold will be reduced when the thermal conductivity of the mold is low. Due to this property, start-up times are sped up and energy costs are reduced. Maximum service temperature is the highest temperature at which the material can continue to operate without losing or deteriorating its properties.

It is common to use mica for platen insulation, but due to its lower compressive strength and high flatness differentiation, MPI is often a more suitable material. If exposed to extremely high pressures, insulation material with low compressive strength can cause mold alignment problems. After the force is removed, the material may undergo a compression set, which is a permanent deformation event.

The uniform temperature of the mold is maintained by tight thickness tolerances or flatness of the material. Parts with tight tolerances have better control of mold temperature. Generally, a significant variation in this tolerance can lead to improper mold temperatures and ultimately product failure.

Why Use a Fabrication Company?

Most common is custom MPI fixtures and pieces to best suit any individual process. To acquire a custom MPI, it is recommended you work with a well-established plastic fabrication company. The right fabrication company near me can help you fabricate a plastic MPI to your specific needs, giving you the best product possible to get the job done. But what exactly does ‘plastic fabrication’ mean?

What is Plastic Fabrication?

In plastic fabrication, a product is designed, manufactured, and assembled from plastic material or composites that contain plastic. Due to the wide range of plastic-based products available today, there is a wide variety of plastic fabrication methods available. Because of their advantages and disadvantages, each method is suitable for the fabrication of certain designs.

Plastic fabrication is popular among manufacturers due to its malleability and cost-effectiveness. Both of these properties make it suitable for a wide range of products across industries.

Thermosetting plastics and thermoplastics are the two main categories of plastic. The two categories are defined by their ability to form desired shapes under pressure and temperature conditions. Thermoplastics are plastics that can be molded repeatedly. They can be softened, melted, and reshaped because of their molecular structure. In contrast, thermosetting plastics, also known as thermosets, cannot be re-molded.

Based on their molecular structure, these two types of plastic are further divided into seven different types. Different industries use these types to produce products according to their specifications. Among the seven types of plastic are:

- Polyethylene Terephthalate

- High-density Polyethylene

- Polyvinyl Chloride

- Polypropylene

- Polystyrene

- Miscellaneous

With so many variables in the production of plastic products, it is important to understand what could go wrong, and the ins and outs of the industries. To expand your knowledge, you can read this article on the industry of fabrication companies. It is always best to go into any business venture as prepared as possible. So read up and make sure to choose the right fabrication company near me for you!

Featured client/products:

Glass Floors | Semi Truck Ramp | Glass Blocks| IT Companies Near Me | SEO Services Near Me | Steel Yard Ramp | Ramp for Loading Dock | Glass Flooring | Loading Dock Ramps | Portable Yard Ramp | Painters Near Me | Interior Painters Near Me