How To Select A Reliable Manufacturer for Aerospace Solenoid Valves

In a solenoid, a coil of wire, the housing, and a moveable plunger are combined. Electricity induces a magnetic field around the coil, which pulls the plunger in. In simpler terms, a solenoid transforms electrical energy into mechanical work. Solenoids have a variety of applications across different fields, and they are used to help move air or fluid during mechanical processes.

Solenoid valves are electrically controlled valves. In the center of the valve is a ferromagnetic core (plunger), which is an electric coil. When the plunger is in the rest position, it closes off a small orifice. Electric current then flows through the coil, creating a magnetic field. Magnetic fields exert an upward force on the plunger, opening the orifice. The opening and closing of solenoid valves are based on this simplistic principle.

These components are a vital part of any electric circuit within a mechanical process. Processes often hinge on the fluid or air that a solenoid is going to move with its plunger, so having a well-constructed solenoid is important to operations. Today we’ll be looking at what to look for when searching for a solenoid system manufacturer.

Air solenoid valves can improve the safety of pneumatic systems if you know how to choose them. In selecting solenoid air valves for your new machine, there are many factors to consider. Among the things to be considered are: What is the port size? What is the required voltage? Do you need individual valves or a manifold? Answering these questions is imperative to building a functional and safe system.

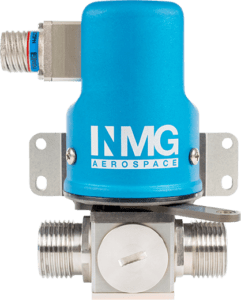

Aerospace Solenoid Valves and Their Functionality

In most flow control applications, it is necessary to control the fluids in the system by starting or stopping the flow in the circuit. A solenoid valve is usually used for this purpose. Since solenoid valves are solenoid-actuated, they can be positioned in remote locations and controlled by simple electrical switches.

Among the most commonly used control elements in fluidics are solenoids. Common uses include shutting off, releasing, dosing, distributing, or mixing fluids. This is why these valves are used in so many applications. It’s generally known that solenoids are fast, have a long service life, are highly reliable, require low control power, and are compact in design.

Finding The Right Manufacturer

Durable components are a must for any aerospace application. Therefore, you will need to devote some time to research in order to find a reliable aerospace solenoid manufacturer. Are you considering CNC machining? Do you have a budget? How complex is your design? You should have answers to all these questions before seeking out help from a manufacturer.

Online reviews can be useful for gauging a company’s timeliness and customer service practices, for example. For a general idea of the team’s compatibility with your niche in the aerospace industry, check reviews from other professionals in your field. Online reviews are, however, only useful when combined with other factors, as the circumstances of any given project can differ considerably and online reviews do not always provide the full picture.

Make it a priority to work with industry-leading quality assurance professionals and get the most out of your next project. Turn to a company with CNC machining experts for both tight tolerances and durable parts. Find companies that set themselves apart from other aerospace solenoid valve manufacturers in the Ohio aerospace industry.

Featured client/products:

Glass Floors | Semi Truck Ramp | Glass Blocks| SEO Services Near Me | Steel Yard Ramp | Ramp for Loading Dock | Glass Flooring | Loading Dock Ramps | Portable Yard Ramp | SEO Company Near Me | SEO Agency Akron | SEO Expert Near Me | Marketing Agencies Near Me | Marketing Agency Akron

Yard Ramps | Yard Ramp